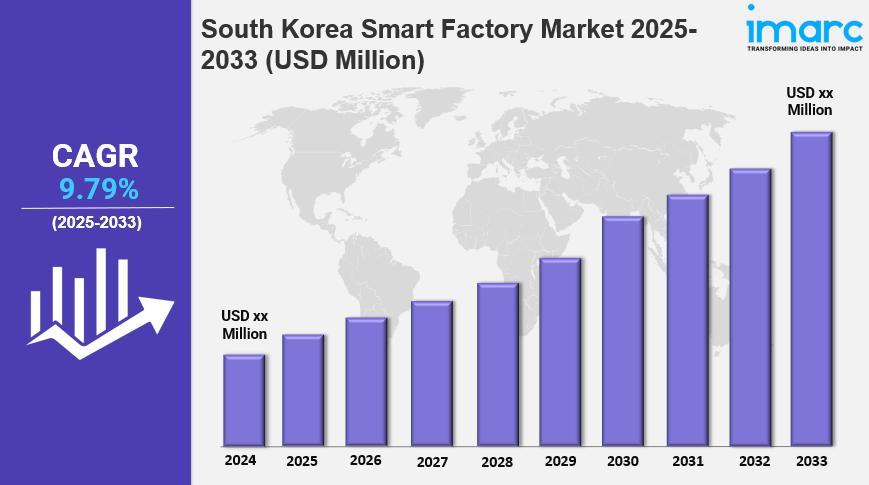

The South Korea smart factory market is projected to grow at a CAGR of 9.79% during the forecast period from 2025 to 2033. The market size is valued at USD 3,699 million. Growth is driven by rising consumer preferences for personalized products, a strong digital ecosystem, and increasing collaborations between industrial and academic institutions. Advanced technologies like IIoT, AI, robotics, and analytics facilitate enhanced manufacturing efficiency and real-time data sharing.

Study Assumption Years

-

Base Year: Not provided in source

-

Historical Year/Period: Not provided in source

-

Forecast Year/Period: Not provided in source

South Korea Smart Factory Market Key Takeaways

-

Current Market Size: USD 3,699 million

-

CAGR: 9.79%

-

Forecast Period: 2025–2033

-

Increasing preference for customized and personalized products is a major growth driver for the market.

-

Strong digital ecosystem development, including advanced communication infrastructure and high internet penetration, supports market expansion.

-

Integration of 5G technology enhances operational efficiency through faster and stable connectivity.

-

Government initiatives offering incentives, R&D grants, and policy frameworks promote smart factory technology adoption.

-

Technological advancements like IIoT, AI, robotics, and advanced analytics drive production cost reduction and quality improvement.

Sample Request Link: https://www.imarcgroup.com/report/ko/south-korea-smart-factory-market/requestsample

Market Growth Factors

The South Korea smart factory market is driven by a significant increase in consumer preference for customized and personalized products. This trend compels domestic companies to enhance production process flexibility and adaptability to meet evolving consumer needs more effectively. Additionally, the strong development of a digital ecosystem, supported by high-speed communication infrastructure and widespread internet accessibility, facilitates seamless manufacturing process connectivity, real-time data sharing, and data-driven decision-making, fostering the growth of smart manufacturing capabilities.

Technological integration remains a critical growth factor. Advancements in industrial Internet of Things (IIoT), artificial intelligence (AI), robotics, and advanced analytics are transforming traditional manufacturing operations. These technologies improve operational efficiency, reduce manual labor, cut production costs, and elevate product quality. The adoption of these cutting-edge technologies in smart factories enables South Korean manufacturers to remain competitive in a dynamic global industrial landscape.

Government support plays a pivotal role in catalyzing market growth. South Korean authorities have implemented several initiatives aimed at fostering an environment conducive to smart factory adoption. These include offering incentives, research and development subsidies, and comprehensive policy frameworks to encourage corporate investments. Moreover, strict data security measures and regulations create a secure operating environment for smart factory solutions. The integration of 5G technology further enhances operational efficiencies by enabling faster and more stable communication within the smart factory ecosystem.

Market Segmentation

Field Device Insights:

-

Industrial Sensors: Devices that detect physical, chemical, or biological properties to monitor manufacturing processes.

-

Industrial Robots: Automated robotic systems designed to perform manufacturing tasks with precision and speed.

-

Industrial Network: Communication systems connecting various devices and components within smart factories.

-

Industrial 3D Printer: Additive manufacturing equipment used for producing complex parts layer-by-layer.

-

Machine Vision System: Technology used for automated inspection, quality control, and guidance in manufacturing.

Technology Insights:

-

Product Lifecycle Management (PLM): Systems managing a product's lifecycle from design to disposal.

-

Human Machine Interface (HMI): Interfaces enabling operator interaction with machinery and systems.

-

Enterprise Resource Planning (ERP): Integrated software managing business processes and resources.

-

Manufacturing Execution System (MES): Systems overseeing and controlling manufacturing operations on the plant floor.

-

Distributed Control System (DCS): Control systems managing complex industrial processes.

-

Industrial Control System: Systems for automation and monitoring in industrial environments.

-

Others: Any other related smart factory technology solutions not specifically categorized.

End User Industry Insights:

-

Pharmaceuticals: Smart factory applications in drug manufacturing and quality assurance.

-

Food and Beverages: Enhanced production and safety controls in food and drink manufacturing.

-

Chemicals: Use of smart technologies for chemical processing and safety management.

-

Oil and Gas: Automated operations and monitoring in petroleum extraction and refining.

-

Automotive and Transportation: Smart manufacturing in vehicle production and logistics.

-

Semiconductor and Electronics: Advanced manufacturing and quality management of electronic components.

-

Aerospace and Defense: Precision manufacturing and quality control in aerospace industries.

-

Others: Additional industries employing smart factory technologies.

Regional Insights

The dominant region in the South Korea smart factory market is the Seoul Capital Area, followed by other key regions such as Yeongnam (Southeast), Honam (Southwest), Hoseo (Central), and Others. Specific market share and CAGR data by region are not provided in the source. The comprehensive regional analysis covers all major geographical markets within South Korea, reflecting the widespread adoption of smart factory technologies.

Key Players

Competitive Landscape

The competitive landscape of the industry has also been examined along with the profiles of the key players.

Customization Note

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us

IMARC Group,

134 N 4th St. Brooklyn, NY 11249, USA,

Email: sales@imarcgroup.com,

Tel No: (D) +91 120 433 0800,

United States: +1-201971-6302

Join our community to interact with posts!