The modern woodworking and metalworking industries expect precision, efficiency, and consistency. Among the technological advancements changing these industries is the miter saw automatic stop system, a radical development indeed. It has transformed an entire philosophy of work-that of repetitively cutting-in an unprecedented manner with accuracy and much less human error or material wastage.

A Glimpse into Automated Stop Technology in Cutting Operations

Automated stop systems constitute huge advancements over techniques that relied on measuring and questioning. These advanced systems hold materials at a preselected length with great accuracy and do away with the requirement that operators must measure, set out the position, and mark each piece independently. Integration of pneumatic digital controls with mechanical precision permits a smooth flow towards turning out areas of increased productivity in a broad spectrum of industries.

The systems work primarily on programmable positioning that would store in memory different cut lengths. The operator inputs desired dimensions, and the system adjusts automatically to accommodate different consonant requirements throughout the workday.

Decisions Regarding Manual Versus Automated Cutting Operations

Manual measures were an almost indispensable part of the cutting operations in the past; it was only by those measurements that a manual operator could make very rough markings before he could begin the actual cutting. This entire process was inherently time-consuming, giving way for mistakes along the way.

These days, a number of challenges were given when it became automatic. In particular, the removal of the human factor in positioning gave excellence in speed and accuracy that could have been unbelievable some way back. There is great assurance that the hundredth cut made on any day would remain just as accurate as the first, a feat nearly impossible through manual methods.

Top Benefits in Production Environments

Automatic stop technology, once implemented in the production floor, has a profound impact on production conditions, the greatest immediate gain being in greatly reducing wastage of material. With digitized positional accuracy applied to every cut, the guesswork is reduced to almost nil whereby raw material is being wasted.

Time savings constitute another great gain. No longer do operators spend crucial minutes measuring and marking every single piece. Instead, they are focused on achieving an efficient workflow loading materials and maintaining quality assurance. Exporting these kinds of labor shifts allows more skilled workers to have a meaningful contribution towards production quality in general.

With automated systems set in place, consistency in large production runs has now been achieved. Whether carving ten pieces or ten thousand, each piece receives one dimension. Such consistency is critical to industries where parts must fit together well or conform strictly to specification criteria.

Integration Within Digital Workshop Systems

Today's automatic stop systems quite often boast connectivity to a wider range of management software for the entire workshop. An integrated solution allows cuts lists to go seamlessly from design packages onto the cutting station, fully bypassing operators and thus minimizing the possibility of error and speeding the transition from design to production.

Real-time monitoring subsequently provides all levels of management with insight into progress, usage of materials, and performance by sewing all of these factors into an organized structure. By reasoning on this record, better decisions can come from an equally reasonable position with regards to resource management and optimization of the workflow.

Safety of the Operator and Ergonomics

Also, much to the benefit of safety, with the usage of an automatic stop system for cut positioning, one could greatly reduce the necessity for bending near machine edges for measuring and marking, thus reducing the number of postural hazards or risk of repetitive strain injuries. By maintaining uniform position, the operator ensures a safe distance away from the cutting fitment while on duty.

By reducing operator fatigue, systems such as these are practically eliminating fatigue. When workers are freed of verified periods of repetitive measuring themselves, they maintain greater focus and alertness during their shifts. Thereby enhanced mental state is good for safer working conditions as well as quality output.

Longevity and Maintenance Considerations

Like any precision device, these automated stop systems require regular care and maintenance for optimum functioning. The durability of the systems means that routine maintenance comprises simple cleaning and occasional calibration checks. The payback on investments becomes apparent rather swiftly when one considers the waste avoidance and productivity gained.

A number of such systems further come equipped with self-diagnostic features that prepare operators in advance of an anticipated defect that could interfere with production. This preventative maintenance measure has greatly reduced the chances of occurrence of unscheduled downtimes, hence massively increasing the lifespan of the very equipment.

Selecting the Right System for Your Operation

Choosing an automated positioning system requires careful consideration of specific operational needs. Factors including typical material sizes, required precision tolerances, production volumes, and available workspace all influence the optimal configuration. Workshop managers should evaluate both current needs and anticipated future growth when making investment decisions.

The learning curve for modern systems has become increasingly gentle as manufacturers prioritize user-friendly interfaces. Most operators become proficient within days of installation, and the intuitive controls mean that training new staff members requires minimal time investment.

Future Developments in Automated Cutting Technology

The trajectory of automated cutting technology points toward even greater integration with artificial intelligence and machine learning. Future systems may predict optimal cutting patterns to minimize waste, automatically adjust for material variations, and learn from historical data to improve performance over time.

Wireless connectivity and cloud-based management systems will likely become standard features, enabling remote monitoring and control capabilities. These advancements will further enhance the efficiency gains already realized through current generation equipment.

Conclusion

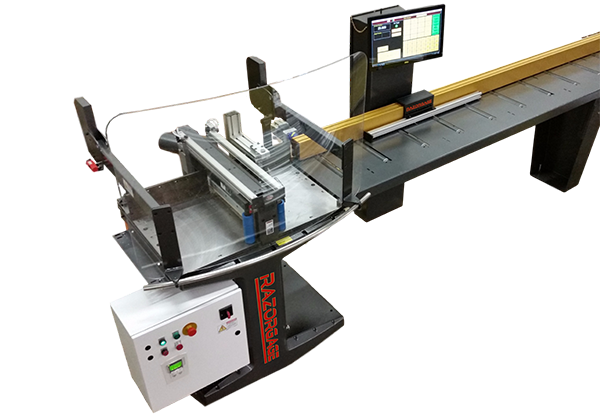

The adoption of automated positioning technology represents more than just an equipment upgrade; it signifies a fundamental shift in how professional workshops approach precision cutting operations. The benefits extend across productivity, quality, safety, and cost-effectiveness, making these systems essential tools for competitive modern operations. For facilities seeking to maximize their capabilities, exploring solutions like the RazorGage Positioner and similar technologies offers a clear path toward operational excellence and sustained competitive advantage in demanding industrial environments.

Frequently Asked Questions

How difficult is it to learn operating an automated stop system?

Most operators become proficient within a few days of hands-on experience. The intuitive digital interfaces are designed for ease of use, and many systems include guided setup procedures that walk users through initial configuration and common operations.

Can these systems handle different material types?

Yes, quality automated positioning systems are designed to accommodate various materials including wood, metal, plastic, and composite materials. The adjustable clamping mechanisms and programmable settings allow for quick transitions between different material types and dimensions.

What kind of precision can be expected?

Modern systems typically achieve accuracy within thousandths of an inch, far exceeding what is possible through manual measurement. The exact precision varies by specific equipment, but even entry-level systems provide remarkable consistency compared to traditional methods.

Is the investment worthwhile for smaller workshops?

The return on investment depends on production volume and the value of materials being processed. Even smaller operations often find that reduced waste and increased productivity justify the initial cost within the first year of operation, particularly when working with expensive materials.

How often does calibration need to occur?

Calibration frequency depends on usage intensity and environmental conditions, but most systems require formal calibration only quarterly or semi-annually. Daily verification checks take just moments and help maintain consistent accuracy between formal calibration sessions.

Join our community to interact with posts!