In the woodworking and manufacturing industries, Saw optimization software has revolutionized how businesses approach material cutting. This technology streamlines the cutting process, reduces waste, and enhances productivity. By intelligently calculating the most efficient cutting patterns, saw optimization software ensures that every piece of wood or material is used to its fullest potential. For professionals and hobbyists alike, this innovation allows for greater precision, cost savings, and faster turnaround times, making it an essential tool in modern workshops.

The Evolution of Saw Optimization

Nowadays, figuring out the best way to cut wood with a saw looks nothing like it did years ago. Back then, people used math by hand, what they remembered from before, or just tried their luck - this usually meant extra scraps and wasted time. Software that plans saw cuts changed how things work, using smart steps inside computers to decide where each slice should go. Because of this shift, shops run faster, pieces match better, corners line up right.

Modern Software Key Features

Out there today, digital tools help plan wood cuts with less hassle. Input your stock sizes, job orders, maybe even preferred grain lines. From that point on, smart routines map out where each blade path works best - factoring in cut width, fiber alignment, leftover piece value. Efficiency jumps when scraps get reused instead of tossed. Fewer tweaks by hand mean hours add up differently at day's end.

Efficiency Gains and Less Waste

Imagine getting more out of every plank - software helps by planning cuts before any blade touches wood. What happens next? Less waste piles up, that is what. Picture tighter layouts where pieces fit like a puzzle, leaving fewer offcuts behind. Over weeks, those tiny gains add up, especially when stacks of lumber move through the shop daily. Money stays in your pocket, trees stay in forests - that kind of quiet win builds slowly. Efficiency sneaks in, not with fanfare, but by simply making better choices, again and again.

Improving Accuracy in Woodworking

Getting things right matters most when shaping wood, particularly on detailed or one-of-a-kind builds. Software tuned for saw work delivers exact guidance on each cut, lessening mistakes made by hand. Thanks to sharp layout plans and clear piece counts, makers achieve steady outcomes from job to job. When measurements align closely, parts join smoothly without gaps. Fewer tweaks mean cleaner assembly. Quality climbs as pieces click into place exactly where intended.

Integration With CNC And Automated Systems

Workshops today often link saw planning software to computer-controlled cutters alongside robotic handling gear. Right off the start, that connection smooths out operations - patterns get calculated fast, then sent straight to equipment without pauses. Machines respond exactly as needed because directions come through clean and clear every time. Precision sticks around even when speed picks up, thanks to smart programs driving mechanical arms and blades. Heavy output runs benefit most since consistency matters more when orders pile up.

User-Friendly Interfaces

Even with tricky math behind it, many saw optimization programs come built with simple screens. Because of this setup, people at every skill level find it easy to enter details, check cut layouts, or change settings when needed. Seeing how pieces fit on screen helps users grasp options fast, while straightforward buttons guide each move. Thanks to visuals and smooth navigation, mastering the system takes less time, opening high-end tools to more workers than before.

Cost Benefits Beyond Just Materials

One big perk of using less material? It saves money, sure. But there is more - cutting smarter slashes trash bills because there is less junk to haul away. Speedier jobs eat up fewer hours on the clock, which trims payroll totals. When slices are mapped out early, machines do not have to work as hard, so they last longer and sip power instead of guzzling it. All these bits add up quietly, making planning tools useful whether you run a garage setup or a sprawling factory floor.

Trends in Saw Optimization

Tomorrow's saw software leans hard on smart algorithms getting sharper every day. With each update, machines learn better ways to slice wood using brains built into code. Alerts pop up before parts wear out, thanks to patterns spotted early. Systems change their approach based on past jobs, growing smarter through use. Tools adapt quietly, needing less guesswork from people who run them. Progress means fewer errors, tighter cuts, less waste without extra effort. What once took trial and error now happens by design, smoothly. Over time, the work feels lighter, faster, somehow closer to second nature.

Conclusion

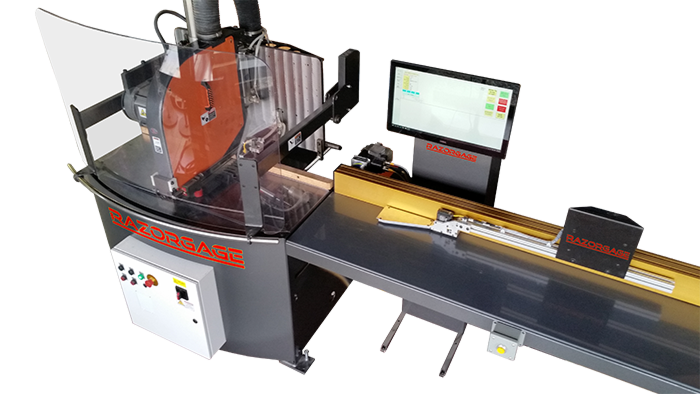

Incorporating saw optimization software into woodworking or manufacturing processes has become essential for maximizing efficiency, precision, and cost-effectiveness. By automating complex calculations and generating optimal cutting patterns, this technology transforms traditional workflows and elevates production standards. For those looking to enhance accuracy and productivity, integrating specialized solutions like RazorGage AngleMaster can further refine cutting techniques, providing unmatched control and performance for both custom projects and large-scale operations. The combination of software intelligence and advanced cutting tools ensures that modern woodworking meets the highest standards of efficiency and quality.

FAQs

Q1: What is saw optimization software?

Saw optimization software is a program that calculates the most efficient cutting patterns for wood or other materials, reducing waste and improving productivity.

Q2: How does saw optimization software save material?

By generating optimal cut sequences and layouts, the software ensures maximum utilization of each piece of material, minimizing scrap.

Q3: Can saw optimization software be used with CNC machines?

Yes, many modern saw optimization tools integrate with CNC and automated cutting systems, allowing seamless execution of calculated cutting patterns.

Q4: Is saw optimization software suitable for small workshops?

Absolutely. User-friendly interfaces and customizable features make it accessible for both small workshops and large manufacturing operations.

Q5: What are the main benefits of using saw optimization software?

The key benefits include reduced material waste, increased precision, lower operational costs, improved workflow efficiency, and enhanced production consistency.

Join our community to interact with posts!