What Does a Pier Builder Actually Do For Waterfront Property

Most folks think a pier builder just shows up, drops some posts in the water, throws a deck on top, and calls it done. I wish it were that simple. Truth is, building a pier is part engineering, part weather fight, and part problem-solving on the fly. Every shoreline acts different. Soil shifts. Water levels lie. Wind changes direction just when you don’t want it to.

A real pier builder starts with conditions first, not materials. You look at depth, bottom type, current, wave action, seasonal changes. Clay bottom? That’s one plan. Soft muck? Whole different approach. Rock ledge? Now we’re bringing heavier equipment and patience. The job isn’t just construction — it’s adaptation. Good builds happen when someone reads the site right, not when they rush to cut boards.

People are sometimes surprised how much planning goes in before the first post is set. Measurements, permits, load calculations, access paths. It’s not glamorous. But skip it and you’ll pay for it later.

Site Conditions Change Everything — And I Mean Everything

No two waterfront builds are twins. Even neighboring properties can behave differently. One bank holds solid. The next one slides after heavy rain. A pier builder learns to respect that fast or learns it the expensive way.

Water depth sounds simple, but it lies through the seasons. That calm shoreline in spring might be two feet lower by late summer. If you don’t plan for fluctuation, your pier ends up too short, or worse, useless half the year. I’ve seen it happen more than once.

Then there’s soil bearing strength. A pier that looks sturdy from above can fail from below if piles aren’t driven deep enough. People don’t see the hidden structure, but that’s the part doing all the work. The visible deck is just the hat on top.

This is also where experience beats theory. Books help. Field time teaches faster.

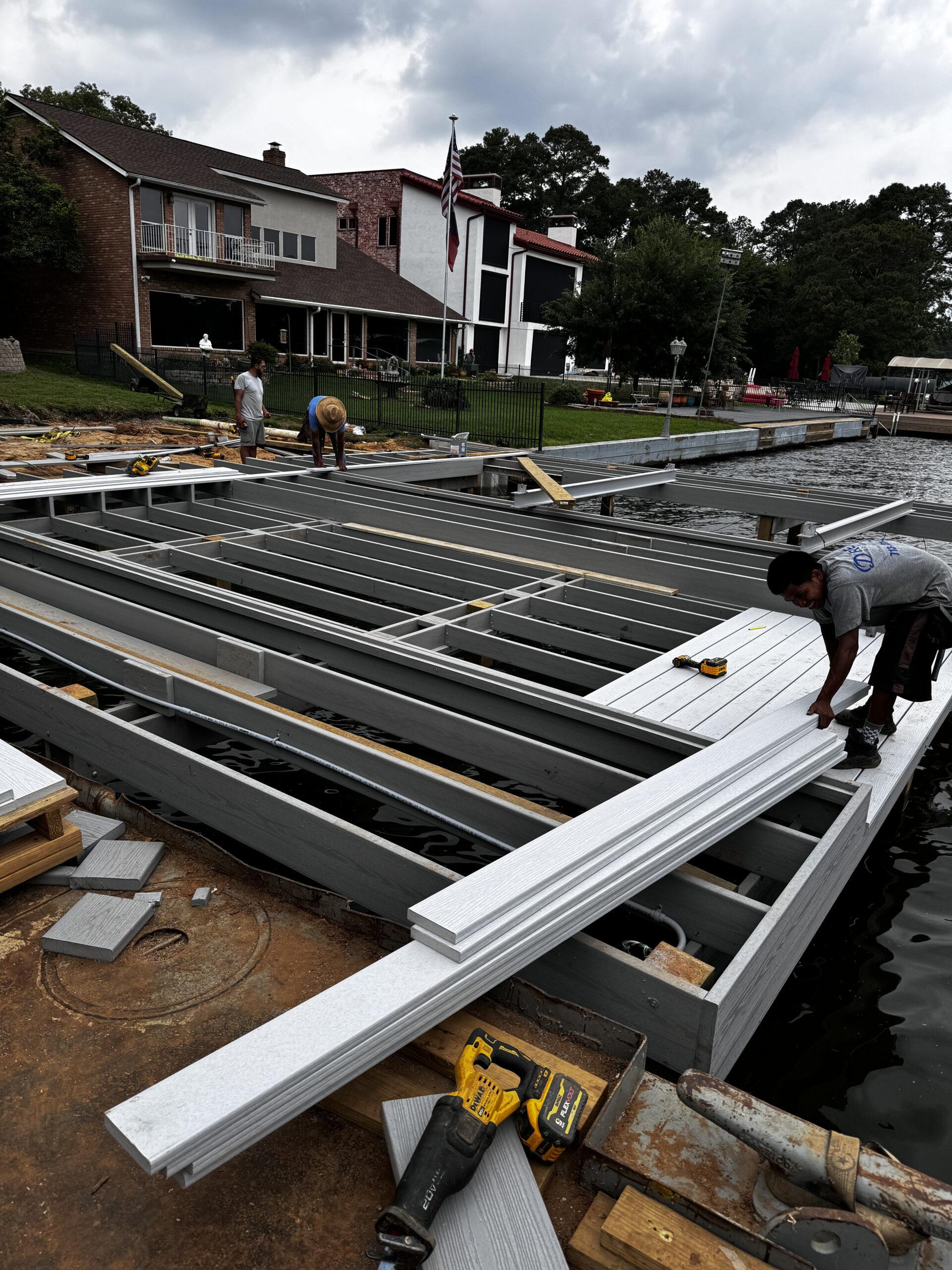

Materials Matter More Than People Want To Admit

Some owners want the cheapest lumber and the fastest timeline. That’s fine — if they’re also okay rebuilding sooner than they planned. Water is rough on materials. Sun is worse. Combine both and weak materials give up quick.

A seasoned pier builder thinks in lifespan, not just install day. Treated lumber ratings, composite options, marine-grade hardware, corrosion resistance — these choices stack up. The bolts and brackets matter just as much as the beams. Maybe more. Hidden failures are the ones that sneak up on you.

Fasteners especially get ignored. Standard hardware rusts out near water faster than people expect. Then connections loosen. Then movement starts. Movement is the beginning of failure, every time.

You don’t need the most expensive materials always. But you do need the right ones for the environment. Big difference.

Design Isn’t Just Looks — It’s Function First

People come in with sketches all the time. Nice drawings. Clean lines. But sometimes the design fights the shoreline. That’s where a pier builder pushes back a little. Not to be difficult — to make sure it works when it’s actually built.

Function beats looks every time on the water. Walk width matters. Turning radius matters. Load points matter. Boat approach angles matter. If you ignore those things, the pier looks good in photos and feels wrong in use.

Height is another big one. Too low and waves wash over it. Too high and boarding a boat turns into a gym workout. The sweet spot depends on water behavior, not preference.

Good design blends use, safety, and durability. Style comes after that. Not before.

Permits, Codes, And The Stuff Nobody Likes Talking About

Here’s the part everyone tries to skip. Permits. Regulations. Shoreline rules. Environmental limits. Setback requirements. It’s not exciting conversation, I know, but it can shut a project down fast if ignored.

A pier builder who’s been around understands local code patterns and approval timelines. Not every area treats waterfront structures the same. Some are strict. Some are confusing. Some change rules mid-year. You learn to check first and build second.

Inspections can also catch shortcuts. That’s actually a good thing, even if it slows things down. Structures over water carry risk. They need oversight.

Honestly, the cleanest jobs are the ones done by the book. Less drama later.

Custom Layouts Change How You Use The Water

This is where custom boat docks start entering the conversation. Because once you go beyond a straight pier, layout planning gets more personal. Usage patterns matter more. Boat size matters. Traffic flow matters.

Some owners fish daily. Some launch kayaks. Some host weekend gatherings. Those uses drive layout decisions. A narrow straight walk won’t serve a multi-boat setup well. A wider platform with branching slips might.

A pier builder often works like a translator here — turning how someone uses the water into physical structure. You ask questions. Watch how they move. See what they tie up. Then shape the design around that behavior.

Custom builds cost more upfront, sure. But they feel right every time you step onto them. That’s the payoff.

Structural Strength Is Mostly Invisible — But Critical

If a pier looks strong, that doesn’t mean it is. Real strength lives below deck level. Pile depth, spacing, cross-bracing, lateral resistance — that’s the skeleton holding everything steady when storms hit.

Wind load and wave load are different beasts. One pushes sideways. The other lifts and drops. A proper pier builder accounts for both. Especially in storm-prone regions. Overbuilding slightly is usually smarter than cutting it close.

Connections carry stress in weird ways too. Angles matter. Joint placement matters. Even board orientation can change how force travels through a structure. Small details stack into big outcomes.

People rarely see this part finished. But it’s the reason the structure is still there years later.

Maintenance Is Part Of The Build — Not An Afterthought

No pier is maintenance-free. None. Doesn’t exist. Anyone who says otherwise is selling something, or guessing.

A responsible pier builder talks about upkeep early. Cleaning schedules. Hardware checks. Surface treatment. Joint inspections. Small repairs done early prevent big repairs later. That’s just reality.

Water structures age differently than land ones. Constant moisture cycles expand and shrink materials. Fasteners loosen. Boards warp. Catching those signs early saves money and headaches.

Owners who plan for maintenance keep their structures longer. The ones who ignore it usually call for major repairs sooner than they expected.

Conclusion — Build It Right Or Build It Twice

Waterfront construction doesn’t forgive sloppy work. A good pier builder knows that and builds accordingly — slower when needed, stronger where it counts, and smarter in design choices. It’s not about fancy tools or smooth talk. It’s about judgment earned from real builds and real failures.

When layouts expand and usage grows, that’s where custom boat docks come into play and the planning gets more personal, more detailed, more site-driven. Do it right once and you enjoy it for years. Rush it and you’ll be fixing it sooner than you want.

That’s the blunt truth of it.

FAQs

How long does a professionally built pier usually last?

With proper materials and solid installation, many piers last twenty to thirty years or more. Lifespan depends heavily on water conditions, material grade, and maintenance habits. Neglect shortens that timeline fast.

Do I always need permits to build a pier?

In most regions, yes. Waterfront structures are usually regulated. Requirements vary by location, but permits and environmental approvals are common and skipping them can cause legal trouble later.

What is the biggest mistake people make with pier projects?

Underestimating site conditions. People plan based on appearance instead of soil strength, water movement, and seasonal level changes. That mismatch causes most structural problems down the line.

Are custom layouts worth the extra cost?

If you use the structure often, absolutely. Custom layouts match real usage patterns and boat types, which makes daily use easier and safer. Generic layouts rarely fit perfectly.

Join our community to interact with posts!