This packaging plays a crucial function in the industry of pharmaceuticals that goes beyond containerisation of the product. Packaging plays a crucial role in protecting the product, patient protection, regulatory compliance and brand identity. As technology advances rapidly in medical and Pharma Packaging, the packaging of pharmaceutical products has become more advanced and ingenious, responding to the demands for global supply, increasing health risks, and the increasing demands of consumers for convenience.

What is Pharma Packaging?

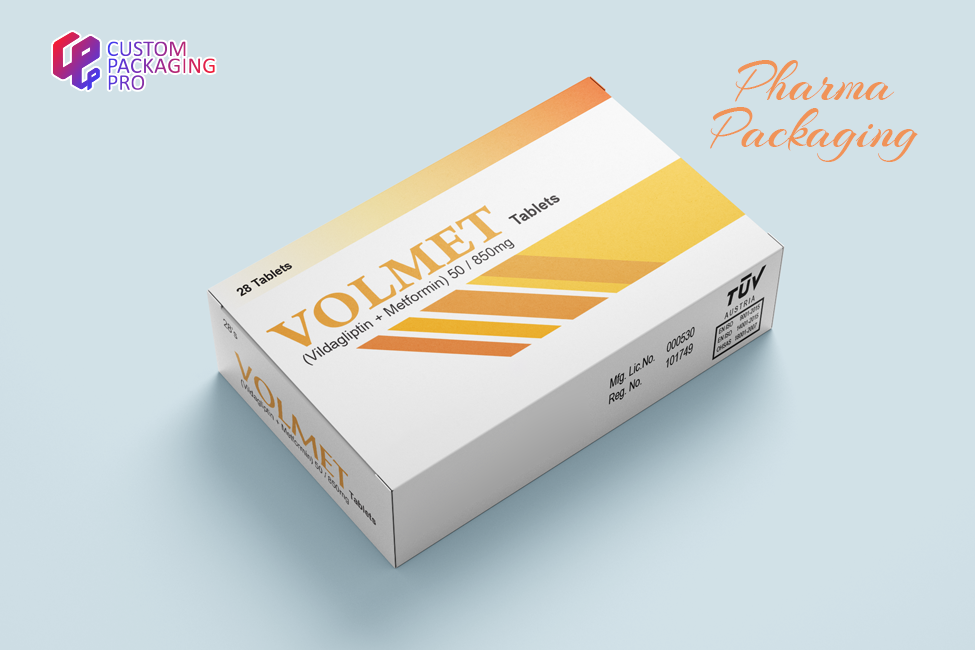

Pharma packaging is the term used to describe the methods and materials employed to protect and encase pharmaceutical products, such as capsules, tablets, liquids, creams, and medical equipment. The packaging is intended to preserve the quality, integrity and security of the drug throughout its shelf-life. This is comprised of main packaging (which is in direct contact with the product, like bottles and blister packs), secondary packaging (outer cartons or boxes) and third-party packaging (bulk handling and transport packaging).

Each layer serves a particular function, making sure that the product is safe, clean, free of contamination, and correctly identified for consumers as well as medical professionals.

Key Features of Effective Pill Packaging

Protecting the Product: Pill Packaging should safeguard the medication from external elements like light, moisture, or air, as well as temperature. For instance, aluminium blister packs as well as amber glass bottles are commonly utilised to protect against water or UV damage.

Tamper Evident and Child Resistant

The packaging for pharmaceuticals should have tamper-proof features that indicate if the product has been tampered with. Closures or caps that are child-proof are also essential, especially when it comes to prescription medicines, in order to avoid accidental consumption by children.

Regulatory Compliance

Pharmaceutical packaging is subject to strict regulations across the globe. Manufacturers must follow the guidelines of organisations like the WHO, the FDA (U.S.), and the EMA (Europe). Packaging should include clear labels indicating dosage, batch numbers, and expiration dates.

User Convenience

Pharma packaging must also focus on accessibility for the patient. Packs that are easy to open, dose markers and labels that are multilingual aid patients to adhere to prescriptions in a timely manner.

Anti-Counterfeiting Measures

Pharmaceutical companies are a major victim of counterfeit products. Innovative packaging solutions such as QR codes, RFID tags, holograms, RFID serialisation, and other methods help confirm authenticity and avoid counterfeiting in the supply chain.

Types of Medicine Packaging

Blister Packs. These are commonly used for capsules and tablets; they provide dose-level protection. Vials and bottles are used for Medicine Packaging or pills, as well as powders, and often have secure caps.

Syringes and Ampoules: Sterile packaging for injectable and vaccines.

Tubes and Sachets are Great in ointments, creams, or powdered medicine.

Pouches along with Strips: Flexible packaging to make it easy to dispense and convenient.

Innovations in Pharma Packaging

Technology advancements mean that the packaging for pharmaceuticals is getting smarter. For instance:

Smart Packaging Sensors and displays allow you to keep track of the temperature of medication or the use of medications.

Sustainable materials: Recycling and biodegradable packaging are growing in popularity to lessen the environmental impacts.

Interactive labels: connected packaging that uses NFC and QR codes can provide patients with digital health information as well as usage instructions and reminders.

The Essential Role of Electronic Packaging in Modern Tech

This packaging is a crucial component of the world of technology. It's more than just enclosing the product, but also making sure that the device is safe, providing a pleasant customer experience and enhancing brand identity. With increasing consumer dependence on technology designed and constructed with care, Electronic Packaging has grown to become a key differentiator. We'll look at the significance of packaging. We'll also discuss the material that is shaping the market, new trends, and useful strategies for designing effective packaging solutions.

Why Electronic Packaging Matters

One of the most important purposes that electronic packages fulfil is protecting the product from chemical, physical and environmental damages. Electronics are frequently prone to environmental factors like shock, moisture, static electricity, and extreme temperatures. Good packaging will ensure that the products are delivered to the user in a perfect operating condition, which reduces returns and dissatisfaction from customers.

For example, anti-static plastics are commonly used to stop electrostatic discharge, which could cause damage to internal components. Similar to that, corrugated cardboard can provide cushioning from impact when moving while remaining light enough to ensure that shipping costs are minimised.

Enhancing User Experience

Packaging creates the first impression that a consumer gets of the product. A well-organised and intuitive design contributes substantially to the experience of unboxing which affects the perceived worth of the product.

Take a look at how the top brands package their electronics. For instance, a smartphone with compartments for the gadget, charging cables and instruction manuals clearly organised and easily accessible. This sort of organisation demonstrates care for detail and convenience and leaves a lasting impression on the person using it.

Supporting Brand Identity

Electronic packaging can be an effective branding tool. It communicates your business's fundamental values, including quality, innovation or environmental sensitivity. For instance, a modern contemporary packaging design for a new device showcases your brand's innovative packaging, while one that emphasises biodegradable materials showcases environmental responsibility.

Distinctive branding elements--such as logos, colour schemes, and clean typography--strengthen brand recall and set products apart in competitive markets. Packaging plays a crucial role in creating a consistent and memorable experience for customers.

Key Materials Used in Barcode Scanner Packaging

The specially designed plastics disperse electrostatic charge, which ensures that delicate components and circuits remain unaffected when they are stored or transported. They are commonly used for products like circuit boards and small electronic components.

Corrugated Cardboard

Corrugated cardboard is a durable, economical, recyclable, and cost-effective alternative for packaging electronic devices. The dual-layer structure offers excellent protection for both small and large electronic components alike. Many companies use corrugated boxes with printed graphics to create branding, but without the cost of sustainability.

Sustainable Alternatives

Eco-conscious businesses are shifting towards eco-friendly plastics, recycled paper and moulded pulp Barcode Scanner Packaging that is biodegradable, and can lower carbon footprints. Sustainable packaging demonstrates an environmental commitment that a lot of consumers actively seek out when purchasing technological products.

Trends in Handsfree Packaging

The trend of minimalism is growing for Handsfree Packaging. Simple lines, neutral colours and simple logos provide a refined look and reduce waste material. This style of design resonates with those who appreciate efficiency and beauty.

Eco-Friendly Solutions

As environmental issues are growing, many brands are making strides towards environmentally friendly packaging methods. Recycling products, recyclable packaging and the reduction of plastics have become top issues. Businesses that have made sustainability an important focus win the favour of eco-conscious buyers.

Smart Packaging Technologies

New technologies like QR codes, NFC tags, and AR-enabled packaging improve the user experience. These interactive features allow users to scan packages to find instructions for installation, product information or information about warranties, adding value and ease of use.

Tips for Creating Effective Electronic Packaging

Select the right materials for the particular device. Anti-static solutions are crucial for electronics that are delicate, and products that are shock-resistant are essential for delicate products.

Focus on the User Experience

Design packaging that is simple to open and easy to use. Give clear instructions and utilise separate compartments for a tidy unboxing experience that is stress-free and effortless.

Reflect Your Brand Values

Make use of colours, typography and materials that match the brand's image. No matter if it's luxury, innovative or sustainability, the packaging you choose to use should enhance your image.

Implement Sustainable Practises

Choose biodegradable, recyclable or reusable products to minimise consumption. Make these initiatives clear so people can appreciate that you are committed to sustainability.

Leverage Smart Tech

Include interactive elements, such as QR codes, to improve the experience of your customers. These tiny touches can lead to unforgettable experiences and increase satisfaction.

Electronic packaging is so much more than a protective cover. It's a chance to communicate regarding your product or brand. Through balancing function, aesthetics and sustainability, companies can design packaging that is not just safe for their devices, but also enhances the user experience, builds brand loyalty and is in line with the needs of today's eco-conscious and tech-savvy consumers.

Join our community to interact with posts!