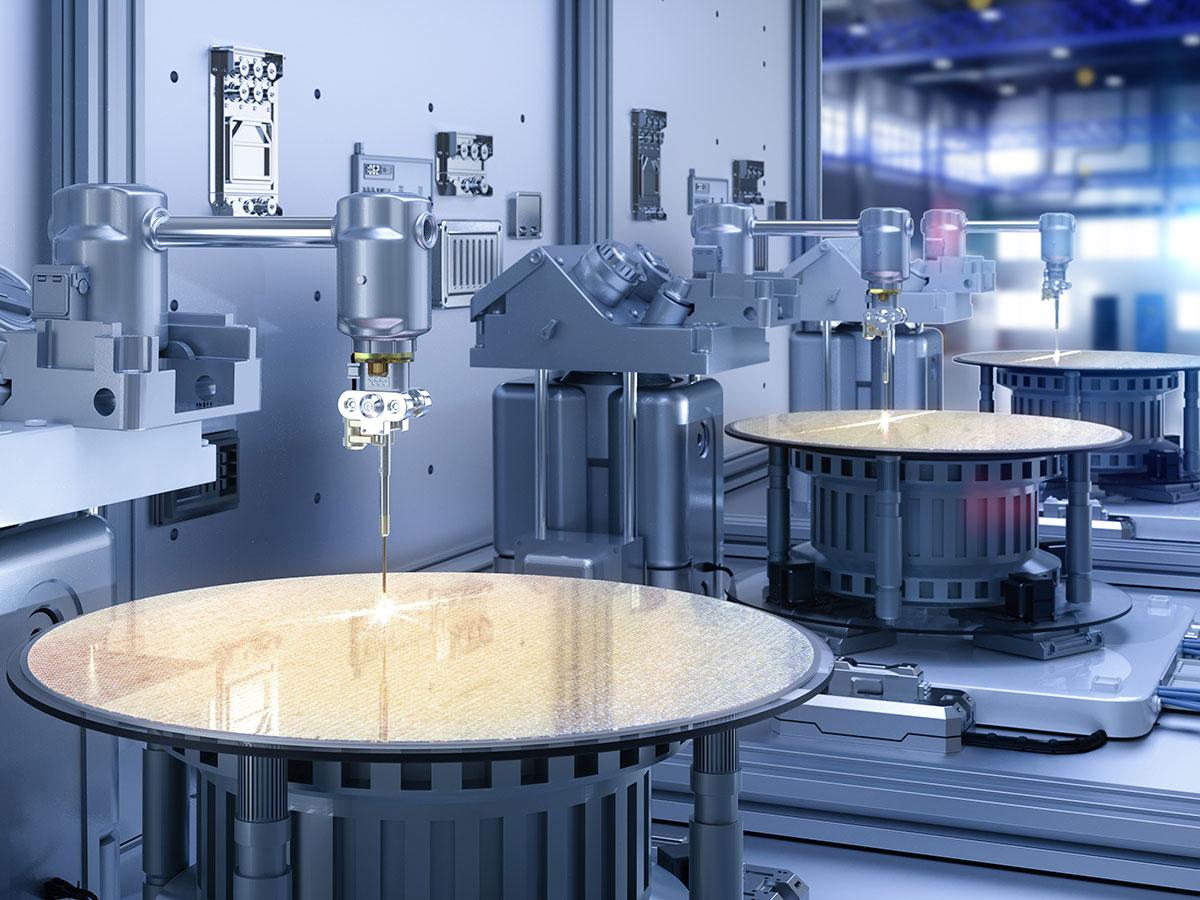

Semiconductor manufacturing equipment (SME) encompasses the highly specialized machinery and tools used in the fabrication and assembly of semiconductor chips — the foundational building blocks of modern electronics. From smartphones and data centers to electric vehicles and industrial automation, the global demand for semiconductors continues to grow exponentially, driving rapid innovation and investment in SME technologies.

The Global Semiconductor Manufacturing Equipment Market Size is projected to reach USD 240.7 Billion by 2033 from USd 113.6 Billion in 2025. The market is expected to register a CAGR of 7.5% from 2025–2033. Key Categories of Semiconductor Manufacturing Equipment

Request Sample: https://m2squareconsultancy.com/request-sample/semiconductor-manufacturing-equipment

The SME ecosystem covers a wide array of processes, each requiring specialized tools:

1. Photolithography Machines

These are critical for defining chip patterns on silicon wafers. Giants like ASML lead with EUV (Extreme Ultraviolet) lithography systems, crucial for sub-7nm nodes.

2. Etching & Deposition Tools

These systems remove and deposit material layers with atomic precision. Leaders include Lam Research, Applied Materials, and Tokyo Electron.

3. CMP (Chemical Mechanical Planarization)

Ensures wafer flatness before layering, enabling multi-patterning and better interconnects.

4. Metrology & Inspection Tools

Used for defect detection, layer thickness measurement, and critical dimension (CD) metrology. Accuracy here prevents costly rework.

Buy Now Reports: https://m2squareconsultancy.com/purchase/79

Emerging Trends in SME (2025 and Beyond)

🔹 AI-Driven Predictive Maintenance

Using machine learning, equipment can now predict failures before they happen, increasing uptime and reducing unscheduled maintenance.

🔹 Green Manufacturing

Newer machines are being designed with energy efficiency and sustainability in mind, aligning with ESG goals across the supply chain.

🔹 Advanced Packaging Equipment

As chiplets and 3D integration rise, back-end equipment like wafer bonding and advanced testers are gaining prominence.

Market Outlook

The global semiconductor equipment market is projected to exceed $120 billion by 2026, fueled by:

-

5G/6G rollouts

-

High-performance computing (HPC)

-

AI chips & edge computing

-

Government incentives (e.g., CHIPS Act in the U.S.)

Semiconductor manufacturing equipment isn’t just about machines — it’s about enabling the next generation of technology. For businesses in the chip supply chain, staying updated on SME trends is essential for staying competitive.

Browse Related URLs:

https://m2squareconsultancy.com/reports/foliar-spray-market

https://m2squareconsultancy.com/reports/low-calorie-food-market

https://m2squareconsultancy.com/reports/semiconductor-manufacturing-equipment

https://m2squareconsultancy.com/reports/service-robotics-market

https://m2squareconsultancy.com/reports/smart-factory-market

https://m2squareconsultancy.com/reports/global-base-oil-market

https://m2squareconsultancy.com/reports/smart-hospital-market

https://m2squareconsultancy.com/reports/single-use-endoscope-market

https://m2squareconsultancy.com/reports/antibody-drug-conjugate-market

https://m2squareconsultancy.com/reports/casino-tourism-market

https://m2squareconsultancy.com/reports/luxury-travel-market

https://m2squareconsultancy.com/reports/digital-signage-market

Join our community to interact with posts!