If you carry or use a knife daily (or any other bladed tool for that matter) you should get nice and familiar with sharpening stones.

These are indispensable tools that are necessary to restore the edge of a knife, or, as stated, any other bladed tool. Axes, knives, chisels, and gouges, among other bladed implements can all be sharpened on stones of appropriate size, shape, and grit.

That being said, there are some things you should know before you buy one, as not all sharpening stones are the same.

1. One stone cannot do it all

This is the most important note on this list. Those that are not familiar with edge restoration and sharpening in general might think all sharpening stones are more or less similar.

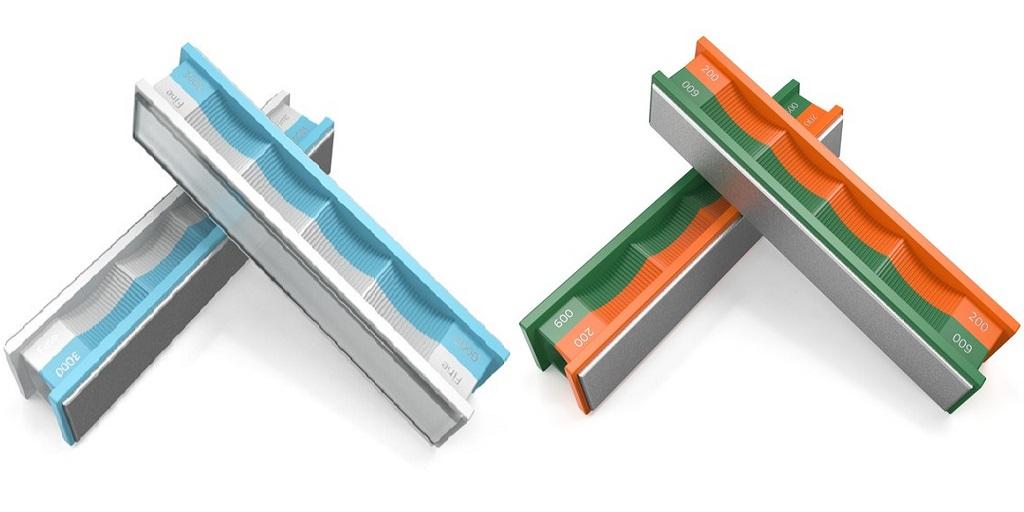

This is not true. Let alone the fact that stones are made in a variety of shapes and sizes, they are all different grits.

Grit is the measure of how coarse the crystal structure, or surface, of the stone is. It is important to recognize that some stones are used for aggressive edge stock removal, others for polishing, and a whole bunch in between.

If you are going to sharpen your tools yourself, you need more than one stone.

2. The higher the grit, the finer the stone

It’s also important to recognize how grit measuring works. The higher the grit, the finer the stone is. A very high grit stone therefore cannot bring back a very dull edge.

Conversely, the lower the grit, the coarser the stone is, and a very coarse stone will ruin a very fine edge.

This is one of the reasons that you need more than one stone.

3. Natural stone grits are approximations

Natural sharpening stones, like Arkansas stones, Belgian coticules, and Japanese and Chinese natural stones, are assigned a grit rating - but it is an approximation.

Because these are natural materials, it is impossible to give a scientifically accurate estimation of how coarse or fine they are.

Therefore, while natural stones are highly useful, it is important to remember that synthetic stones are more precise.

4. Over time, your stone will need to be flattened

As you use your sharpening stone, the surface will become concave through use; the way to restore this is with another stone known as a flattening stone that will bring back the flat surface.

5. Applying oil to the stone is a non-reversible process

Many stones are sold with honing oils or solutions that are supposed to help prevent the surface of the stone from getting clogged with swarf, and which are supposed to improve sharpening efficiency by “floating away” said swarf.

That may be true, but if you apply honing oil or solution to a stone, you will not be able to remove it. It’s safer to use water; water works just the same way and will eventually evaporate from the stone.

Where to Get a New Sharpening Stone for Your Shop

Looking for a new sharpening stone, or a series of bench stones, for your shop? Visit White Mountain Knives first. Not only do they carry stones, they carry sharpening rods and systems as well - everything you could need and more.

For more information about Small Gerber Knife and Zero Tolerance Pocket Knife Please visit: White Mountain Knives, LLC.

Join our community to interact with posts!