Composites Market Outlook (2025–2032): Growth Driven by Lightweight Innovation and Renewable Energy Expansion

Global Composites Market Overview

The Global Composites Market was valued at USD 132.98 billion in 2024 and is projected to reach USD 249.82 billion by 2032, growing at a CAGR of 8.2% during the forecast period. This strong growth is primarily driven by the rising demand for lightweight, high-strength, and durable materials across industries such as automotive, aerospace, wind energy, construction, and electronics.

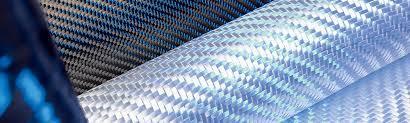

Composites are engineered materials created by combining two or more distinct components, typically a reinforcement material such as carbon fiber, glass fiber, or natural fiber, with a matrix material including polymer, metal, or ceramic. This combination results in materials that offer superior mechanical performance, corrosion resistance, and weight efficiency compared to traditional materials like steel and aluminum.

Rapid technological advancements in fiber reinforcement, resin chemistry, and manufacturing processes have expanded composite applications worldwide. The growing focus on fuel efficiency, carbon reduction, and sustainability continues to accelerate the adoption of fiber-reinforced polymers (FRP), polymer matrix composites, and advanced composite systems.

♦ Request a Free Sample Copy or View Report Summary:https://www.maximizemarketresearch.com/request-sample/34243/

Market Dynamics

Trend: Rapid Adoption of Lightweight Materials in Transportation

The transportation sector is witnessing a major shift toward lightweight composite materials. Automotive and aerospace manufacturers are increasingly replacing conventional metals with Glass Fiber Reinforced Polymers (GFRP) and Carbon Fiber Reinforced Polymers (CFRP) to improve performance and energy efficiency.

In the automotive sector, composites enable 10–15% vehicle weight reduction, resulting in improved fuel economy and extended battery range for electric vehicles. With global EV production expected to exceed 30 million units by 2030, demand for lightweight composite components is rising significantly.

In aerospace, advanced composites account for over 50% of the structural weight of modern aircraft such as the Boeing 787 and Airbus A350. These materials offer enhanced fatigue resistance, reduced maintenance requirements, and improved fuel efficiency. Similar benefits are driving composite adoption in rail, marine, and logistics sectors, reinforcing long-term market growth.

Rising Demand from Wind Energy Sector

The rapid expansion of wind energy installations has emerged as a major growth driver for the composites industry. Wind turbine blades rely heavily on glass fiber composites, thermoset resins, and polymer matrix materials due to their exceptional strength-to-weight ratio and fatigue resistance.

In 2024, global wind capacity additions exceeded 110 GW, supporting strong demand for composite materials. More than 80% of turbine blades are manufactured using GFRP combined with epoxy and polyester resins. As blade lengths exceed 80–100 meters, the need for lightweight and durable materials continues to rise.

The expansion of offshore wind projects in China, the United States, and Northern Europe is further strengthening demand. Government commitments toward carbon neutrality and renewable energy targets are expected to significantly boost composite consumption in the coming decades.

Market Restraint: Limited Recycling Infrastructure

Despite strong growth prospects, limited recycling capabilities remain a major challenge for the composites market. Thermoset composites, which dominate many applications, cannot be remelted due to their cross-linked molecular structure, making conventional recycling difficult.

Currently, only 15–20% of composite waste is recoverable globally. Industries such as wind energy, automotive, and aerospace generate large volumes of composite waste after product life cycles end. Retired wind turbine blades, in particular, pose major environmental concerns.

Although recycling technologies such as pyrolysis, solvolysis, and mechanical grinding are emerging, they remain expensive and difficult to scale. Regulatory pressure in Europe and North America may further impact market growth in regions lacking adequate recycling infrastructure.

Global Composites Market Segment Analysis

By Fiber Type

Based on fiber type, the market is segmented into:

-

Glass Fiber Composites

-

Carbon Fiber Composites

-

Natural Fiber Composites

Glass fiber composites dominated the market in 2024 due to their cost-effectiveness, mechanical strength, corrosion resistance, and wide industrial applicability. These materials are widely used in automotive, marine, wind energy, construction, and electrical applications.

Glass fiber offers substantial weight reduction while maintaining durability and structural performance. Its compatibility with various resin systems supports its widespread adoption across multiple manufacturing processes.

By Resin Type

By resin type, the market is classified into:

-

Thermoset Composites

-

Thermoplastic Composites

Thermoset composites are expected to maintain dominance throughout the forecast period. These materials form permanent cross-linked structures during curing, offering excellent dimensional stability, high strength, and long-term durability.

Thermosets are extensively used in aerospace, automotive, wind energy, marine, and construction sectors for structural panels, reinforcements, and load-bearing components. While thermoplastic composites are gaining attention, large-scale adoption remains in the developmental stage.

♦ Download Sample Report Here : https://www.maximizemarketresearch.com/request-sample/34243/

Regional Insights

Asia Pacific Dominates the Global Market

Asia Pacific accounted for the largest share of the global composites market in 2024 and is expected to maintain its leadership through 2032. Rapid industrialization, expanding manufacturing capabilities, and strong demand from automotive, aerospace, and renewable energy sectors support regional growth.

Countries such as China, Japan, South Korea, and India play a central role in shaping market expansion. China and India are witnessing strong growth in EV manufacturing, driving demand for CFRP and GFRP materials. Japan and South Korea remain leaders in high-performance aerospace composites.

Asia Pacific also leads global wind turbine installations, strengthening demand for FRP materials. Government investments in sustainable infrastructure, bio-composites, and advanced manufacturing technologies further reinforce the region’s market position.

♦ Make Smarter Decisions in 2026 — Get Your Research Report Now: https://www.maximizemarketresearch.com/market-report/global-composites-market/34243/

Competitive Landscape

The global composites market is highly competitive, with the presence of multinational corporations, specialized manufacturers, and emerging regional players. Leading companies include:

-

Hexcel Corporation

-

Toray Industries Inc.

-

Owens Corning

-

SGL Carbon

-

Solvay

-

Teijin Limited

These players focus on product innovation, advanced material development, and strategic collaborations with aerospace, automotive, and renewable energy companies. Capacity expansions, mergers, and acquisitions remain key strategies to enhance market presence.

Mid-sized companies such as Gurit, Saertex, AOC, and Polynt-Reichhold compete by offering customized and cost-efficient composite solutions. Emerging manufacturers in Asia are intensifying competition through low-cost production and technological advancements.

Recent Developments

In October 2024, Hexcel announced new strategies for high-rate aerospace composites, focusing on sustainable and scalable manufacturing processes such as out-of-autoclave curing and compression molding.

In November 2024, Toray Advanced Composites acquired Gordon Plastics’ assets to strengthen its thermoplastic composite portfolio. The acquisition enhanced R&D and production capacity for high-performance fiber-reinforced materials used in industrial and energy applications.

Future Outlook

The Global Composites Market is poised for sustained expansion through 2032, supported by rising demand for lightweight materials, renewable energy investments, and transportation innovation. Advancements in resin systems, automation, digital manufacturing, and recycling technologies are expected to further enhance market growth.

Increasing focus on sustainability, bio-based composites, and circular economy practices will shape future industry developments. As industries continue to prioritize energy efficiency and environmental responsibility, composites will remain a core material solution worldwide.

◉ Get Market Research Latest Trends

Global Commercial Helicopter Market https://www.maximizemarketresearch.com/market-report/global-commercial-helicopter-market/114756/

High Voltage Electric Heater Market https://www.maximizemarketresearch.com/market-report/high-voltage-electric-heater-market/124402/

Torque Vectoring Market https://www.maximizemarketresearch.com/market-report/torque-vectoring-market/185108/

About Maximize Market Research:

Maximize Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Maximize Market Research:

3rd Floor, Navale IT Park, Phase 2

Pune Bangalore Highway, Narhe,

Pune, Maharashtra 411041, India

sales@maximizemarketresearch.com

+91 96071 95908, +91 9607365656

Join our community to interact with posts!