Thin wall food container moulds play a crucial role in the production of lightweight, durable, and safe food packaging. These moulds are designed to produce containers with thin walls that maintain structural integrity while being cost-effective. Understanding how to view and evaluate these moulds can help manufacturers optimize production and ensure high-quality products.

Understanding the Mould Design

The design of a thin wall food container mould is crucial to producing containers with consistent thickness, strength, and aesthetic appeal. The mould must be able to handle the specific materials used for food packaging, ensuring proper material flow, cooling, and mould closure.

Key Features of Mould Design

Precision and Uniformity: The mould must ensure that the wall thickness is uniform across the entire container to maintain structural integrity and prevent defects.

Material Compatibility: Moulds should be designed to work with specific food-safe plastic materials, such as polypropylene or PET, that offer both safety and durability.

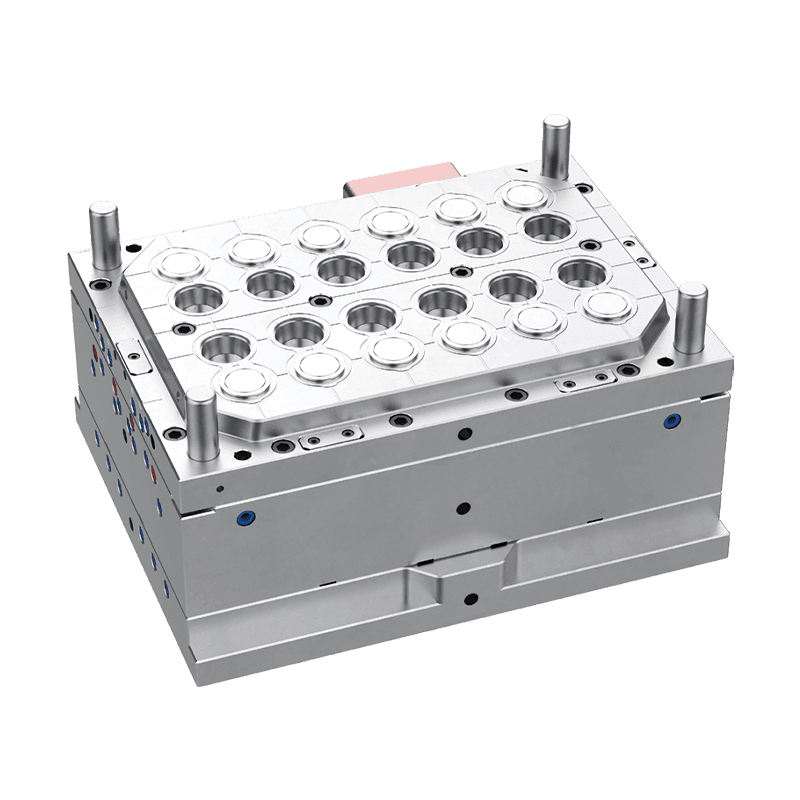

Mould Cavities: Depending on the production scale, moulds can be single or multi-cavity, with multi-cavity moulds increasing production efficiency.

Moulding Process Considerations

The moulding process is critical in producing high-quality thin wall food containers. The design of the mould influences how efficiently the plastic is injected, cooled, and ejected from the mould cavity.

Important Process Factors

Injection Speed: A high injection speed is essential for achieving thin walls, as it allows for even material distribution without compromising quality.

Cooling Efficiency: Efficient cooling channels within the mould help in faster production cycles and prevent warping or uneven thickness in the final product.

Mould Maintenance: Regular maintenance is necessary to ensure the mould's longevity and prevent issues such as clogs or damage, which can affect production.

Evaluating Mould Performance

To ensure the mould performs as expected, it's important to evaluate several factors that affect the quality of the food containers produced.

Key Evaluation Points

Durability: The mould must be made from high-quality, durable materials that can withstand the stresses of repeated use.

Cycle Time: Faster cycle times contribute to higher productivity, so evaluating the mould's ability to produce containers efficiently is key.

Final Product Quality: Inspecting the quality of the final product is essential. Thin wall food containers should be lightweight yet strong, without defects such as warping, bubbles, or inconsistent thickness.

https://www.food-container-mold.com/product/sauce-cup-mould-series/integrated-sauce-cup-mold-1oz5oz.html

The Disposable Plastic Integrated Sauce Cup Mold (1OZ-5OZ) is a high-quality mold designed for the production of disposable sauce cups ranging from 1 ounce to 5 ounces. This mold is essential for manufacturers aiming to produce uniform, high-precision disposable sauce cups efficiently. Constructed with durable materials, the mold ensures longevity and consistent performance.

Join our community to interact with posts!