Precision and efficiency are vital in modern construction, where delays and material errors can significantly impact project costs. Manual rebar bending is often slow, labor-intensive, and inconsistent, which is why the automatic rebar bending machine has become an essential tool for contractors and fabrication facilities aiming for speed, accuracy, and safety.

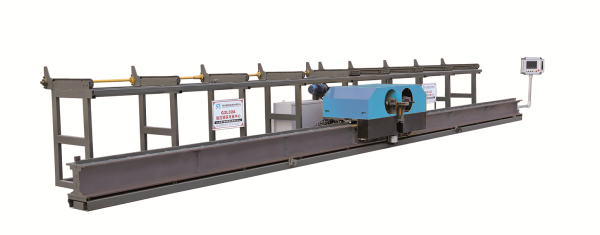

The automatic rebar bending machine uses advanced CNC technology to bend steel bars into precise shapes required for reinforced concrete structures. Its automated system ensures uniform angles and accurate lengths, eliminating human errors and reducing material waste. This results in higher-quality outputs and greater productivity, making it ideal for residential, commercial, and infrastructure projects.

One of the key advantages of the automatic rebar bending machine is its speed. The machine can process large volumes of rebar in a fraction of the time it would take manually, enabling contractors to meet tight deadlines efficiently. With programmable bending patterns, it accommodates a wide range of rebar sizes and shapes, providing flexibility for various construction needs.

Durability and reliability are central features of the automatic rebar bending machine. Built with robust components and high-strength steel, it can handle heavy-duty operations without compromising performance. This ensures consistent results even under continuous use, reducing maintenance costs and downtime while extending the machine’s lifespan.

Safety is another important benefit. Manual rebar bending exposes workers to risks such as repetitive strain injuries and accidental cuts. The automatic rebar bending machine automates the process, minimizing physical labor and protecting operators. This creates a safer work environment and helps construction teams maintain productivity without compromising safety standards.

The automatic rebar bending machine is also highly versatile. It can handle complex bending tasks, varying rebar diameters, and customized shapes with ease, making it suitable for diverse projects. Its user-friendly CNC interface allows operators to program bending specifications quickly, ensuring precision and consistency across every task.

In conclusion, the automatic rebar bending machine transforms rebar processing by combining automation, accuracy, and durability. It enhances productivity, reduces labor costs, and ensures high-quality results on every construction project. Investing in this machine is a strategic choice for contractors seeking efficiency, safety, and reliable performance in modern construction workflows.

Join our community to interact with posts!