In today’s fast-paced manufacturing industry, Online Sheet Metal Bending Services are transforming how businesses get parts produced. From small-scale prototypes to large industrial applications, companies are leveraging advanced bending technologies to create accurate, durable, and cost-effective components. With just a few clicks, customers can upload designs, get instant quotes, and have precision-bent metal parts delivered right to their door.

The Evolution of Sheet Metal Bending

Sheet metal bending has been around for decades, but the shift to Online Sheet Metal Bending Services has revolutionized accessibility. Traditionally, bending projects required multiple consultations, in-person visits, and long lead times. Today, manufacturers can offer on-demand, digitally driven services that streamline the entire process from design to delivery.

Digital bending solutions provide more than just speed—they offer accuracy, repeatability, and flexibility for a wide range of applications. This makes them ideal for industries like automotive, aerospace, architecture, and consumer products.

Why Businesses Choose Online Sheet Metal Bending Services

Speed and convenience are just the beginning. When companies opt for Online Sheet Metal Bending Services, they get several critical advantages:

-

Instant Quoting & Ordering – No more waiting days for price estimates; advanced software calculates bending costs in minutes.

-

Precision Engineering – Automated CNC bending ensures that every part matches exact design specifications.

-

Wide Material Selection – From aluminum to stainless steel, online services provide flexibility for all project types.

-

Low to High Volume Flexibility – Whether it’s a single prototype or a bulk production run, orders can be scaled easily.

Steel Sheet Metal Bending Services for Heavy-Duty Applications

When projects require strength and resilience, Steel Sheet Metal Bending Services become the preferred choice. Steel’s durability makes it ideal for structural parts, industrial enclosures, and high-stress applications.

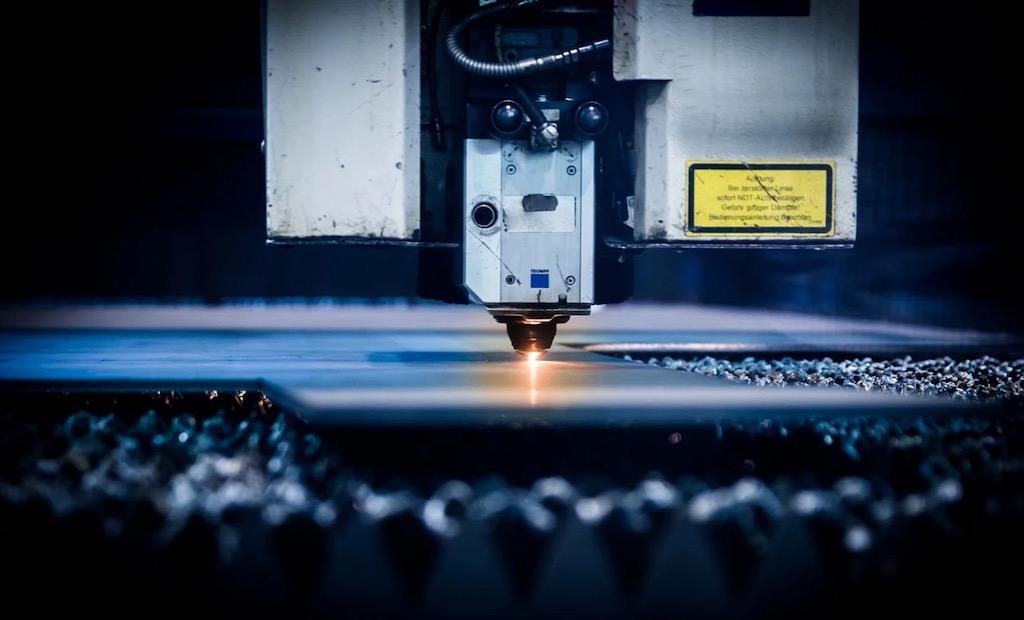

Using modern CNC press brakes, manufacturers can bend steel sheets with extreme precision, maintaining structural integrity while meeting exact tolerances. Steel’s versatility also allows for both functional and aesthetic applications—making it equally valuable in machinery and architectural designs.

Sheet Metal Bending Solutions for Every Industry

The demand for Sheet Metal Bending Solutions spans across industries. Aerospace companies require lightweight but durable components, automotive manufacturers need complex geometries for body panels, and electronics brands rely on precise enclosures to protect sensitive parts.

Custom bending solutions make it possible to produce parts that fit perfectly into each application, regardless of complexity. This adaptability helps businesses reduce waste, cut costs, and improve production efficiency.

Industrial Sheet Metal Bending Service: Meeting Large-Scale Demands

When large volumes and tight deadlines collide, an Industrial Sheet Metal Bending Service can be a game-changer. These services combine high-capacity machinery with skilled operators to handle heavy production loads without compromising accuracy.

For example, large-scale HVAC ducting, factory machinery panels, and transportation components often require complex bending patterns. With industrial-grade capabilities, manufacturers can ensure consistent quality across thousands of identical parts.

The Role of Sheet Metal Bending Experts

Behind every precision-formed metal part are Sheet Metal Bending Experts who understand both the art and science of bending. Their expertise ensures that designs are translated into physical parts without errors, material stress points, or structural weaknesses.

Expert input also helps with design optimization—sometimes a slight change in bend radius or tooling choice can drastically improve performance and reduce costs. This blend of human skill and automated technology delivers unmatched results.

How Online Sheet Metal Bending Services Work

The workflow for Online Sheet Metal Bending Services is designed to be simple, fast, and transparent:

-

Upload Your Design – CAD files are uploaded directly to the service platform.

-

Instant Quotation – The system calculates material, labor, and shipping costs in seconds.

-

Manufacturing Begins – Automated bending machines follow the digital design precisely.

-

Quality Checks – Parts undergo inspection to ensure accuracy and durability.

-

Delivery – Completed parts are shipped to your location, ready for use.

This streamlined process eliminates unnecessary delays and gives customers more control over timelines and budgets.

Benefits of Choosing an Online Approach

Shifting to Online Sheet Metal Bending Services offers clear advantages:

-

Faster Turnaround Times – Projects that once took weeks can now be completed in days.

-

Lower Operational Costs – No need for extensive in-house bending equipment.

-

Global Access – Businesses can work with top-tier bending providers regardless of location.

-

Consistent Quality – CNC automation ensures identical results across batches.

These benefits make online bending the go-to solution for both startups and established manufacturers.

Customization Without Compromise

Modern Online Sheet Metal Bending Services allow for deep customization. Designers can choose bend angles, hole patterns, finishes, and materials to suit their exact needs. Even complex multi-bend parts can be produced without significant cost increases, thanks to precision tooling and software-guided bending paths.

This level of customization empowers engineers to push design boundaries without worrying about manufacturing limitations.

Integrating Bending into Complete Manufacturing Workflows

While bending is a critical step, it often forms part of a larger production process. Many providers offer Sheet Metal Bending Solutions alongside laser cutting, welding, and surface finishing, creating a complete manufacturing pipeline. This integration helps businesses reduce logistical challenges and maintain better quality control.

The Future of Online Sheet Metal Bending

As automation and AI-driven manufacturing continue to advance, Online Sheet Metal Bending Services will become even more efficient. We can expect faster quoting systems, improved material utilization, and smarter bending algorithms that minimize errors and material waste.

In the future, customers may even see fully automated order-to-delivery systems where human intervention is only required for design input.

Conclusion: A Smarter Way to Bend Metal

From custom one-off prototypes to large-scale industrial production, Online Sheet Metal Bending Services provide the flexibility, speed, and precision modern industries demand. By combining advanced CNC technology with expert craftsmanship, businesses can get the exact parts they need without unnecessary delays or costs.

Whether you need Steel Sheet Metal Bending Services for heavy-duty components or specialized Sheet Metal Bending Solutions for a unique project, today’s online platforms make high-quality results more accessible than ever. With Sheet Metal Bending Experts guiding the process and Industrial Sheet Metal Bending Service capabilities ready for large-scale demands, the future of bending is here—and it’s online.

Join our community to interact with posts!