MARKET OVERVIEW

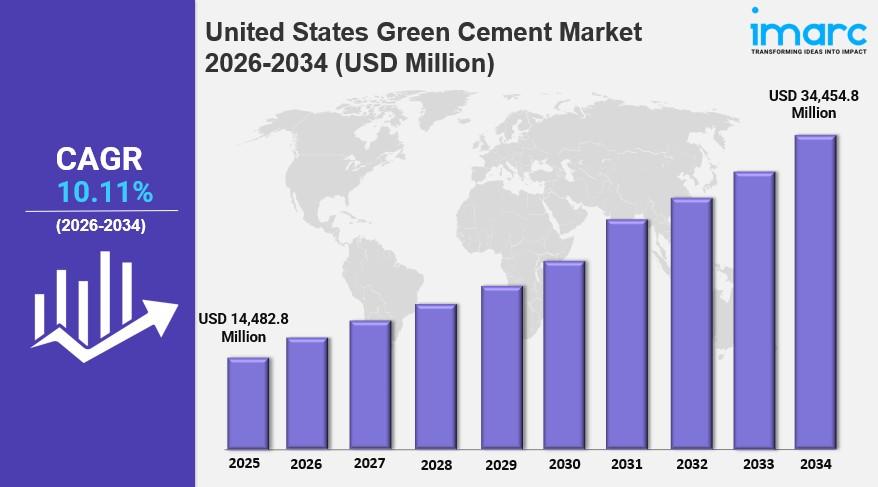

The United States Green Cement Market size reached USD 14,482.8 Million in 2025 and is projected to grow to USD 34,454.8 Million by 2034. The market is expected to expand at a CAGR of 10.11% during the forecast period from 2026 to 2034. This growth is propelled by increasing environmental regulations, demand for sustainable construction, and government incentives promoting eco-friendly building materials.

STUDY ASSUMPTION YEARS

● Base Year: 2025

● Historical Year/Period: 2020-2025

● Forecast Year/Period: 2026-2034

UNITED STATES GREEN CEMENT MARKET KEY TAKEAWAYS

● Current Market Size: USD 14,482.8 Million in 2025

● CAGR: 10.11% during 2026-2034

● Forecast Period: 2026-2034

● The market growth is driven by stringent environmental regulations and rising awareness of carbon emissions from traditional cement.

● Government incentives and LEED certification standards encourage the use of eco-friendly building materials.

● Technological advancements in green cement manufacturing and redevelopment projects contribute to market expansion.

● Construction companies are increasingly adopting low-carbon alternatives to support sustainable development.

● Challenges include high production costs, lack of standardized regulations, and limited raw material availability.

Sample Request Link: https://www.imarcgroup.com/united-states-green-cement-market/requestsample

MARKET GROWTH FACTORS

Growing environmental awareness, supportive government policies, and an emphasis on green building practices are primary growth drivers. The United States green cement market benefits from corporate sustainability commitments and continual innovations in cement manufacturing techniques, leading to increased demand for eco-friendly cement across residential and commercial sectors. These factors collectively stimulate market expansion and promote the adoption of sustainable building materials.

Stringent environmental policies and incentives have a significant influence on market growth. Federal and state governments promote sustainable construction through incentives, procurement mandates, and environmental regulations. These policies motivate cement manufacturers to implement low-emission production processes and greener mix designs, while subsidies and pilot schemes finance cleaner industrial technologies. This regulatory environment accelerates innovation and market penetration of green cement solutions.

Technological advancements are transforming cement manufacturing and application. Substitute materials such as industrial waste and natural substances reduce emissions notably. New manufacturing techniques enhance energy efficiency and minimize waste. Carbon capture, mineralization, and electrochemical cement technologies receive growing support from both government and private investments. Smart manufacturing tools and automation systems optimize production efficiency, enabling cost reduction and scalability essential for market growth.

MARKET SEGMENTATION

Breakup by Product Type:

● Fly Ash-Based: Utilizes industrial by-product fly ash, reducing energy consumption and increasing durability in construction.

● Slag-Based: Incorporates furnace slag, an industrial recycled material, enhancing strength and sustainability.

● Limestone-Based: Uses limestone as a primary material, offering lower carbon emissions than conventional cement.

● Silica Fume-Based: Made from silica fume, a by-product of silicon metal and ferrosilicon alloys, providing enhanced properties.

● Others: Includes additional alternative raw materials contributing to green cement production.

Breakup by End Use Industry:

● Residential: Application of green cement in constructing sustainable homes and housing projects.

● Non-Residential: Use in commercial buildings and industrial facilities prioritizing eco-friendly materials.

● Infrastructure: Deployment in public works and infrastructure development emphasizing low-carbon construction.

Breakup by Region:

● Northeast: Regional market for green cement covering northeastern states.

● Midwest: Includes midwestern states with growing sustainable construction activities.

● South: Southern U.S. region with increasing demand for green cement in construction.

● West: Western states contributing to market growth through green building initiatives.

REGIONAL INSIGHTS

The United States represents the largest market for green cement in the North American region, driven by a significant increase in environmental concerns and government initiatives such as those by the EPA. This dominance underscores the region's commitment to reducing carbon emissions through sustainable building practices and advanced technology adoption.

Speak to An Analyst: https://www.imarcgroup.com/request?type=report&id=2895&flag=C

RECENT DEVELOPMENTS & NEWS

In May 2025, Microsoft partnered with low-carbon cement startup Sublime Systems to reduce emissions from data center construction. The deal allows Microsoft to claim emissions reductions despite indirect use of the cement, targeting Scope 3 emissions and supporting carbon negativity by 2030.

In January 2025, Hoffmann Green Cement Technologies expanded its licensing agreement with Hoffmann Green USA to cover 25 eastern U.S. states. The agreement includes an �8 million entry fee, exclusive rights for technology transfer, sublicensing provisions, and royalty payments, promoting wider adoption of low-carbon cement solutions.

KEY PLAYERS

● Microsoft

● Sublime Systems

● Hoffmann Green Cement Technologies

● Hoffmann Green USA

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

ABOUT US

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

CONTACT US

IMARC Group,

134 N 4th St. Brooklyn, NY 11249, USA,

Email: sales@imarcgroup.com,

Tel No: (D) +91 120 433 0800,

United States: +1-201971-6302

Join our community to interact with posts!