Gutters are often overlooked when considering a home or building’s structure, but they play a critical role in protecting roofs, walls, and foundations from water damage. Properly installed gutters efficiently channel rainwater away from a building, preventing leaks, erosion, and costly repairs. In modern construction, gutter machines have revolutionized the way gutters are produced and installed, providing precision, efficiency, and long-lasting results.

What Are Gutter Machines?

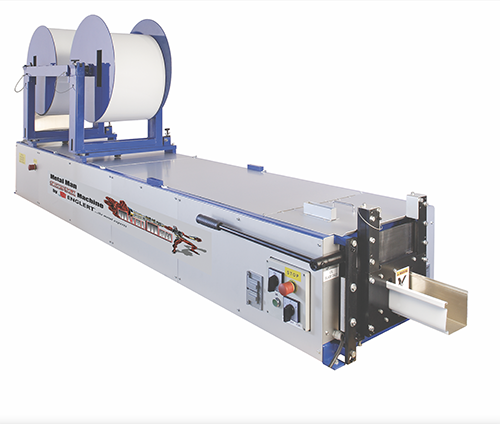

Gutter machines are specialized equipment designed to fabricate gutters and downspouts on-site from rolls of metal. Instead of relying on pre-cut, sectional gutters, these machines allow contractors to produce seamless gutters that perfectly match the dimensions of a building. The machines work with materials like aluminum, steel, copper, and zinc, and they can form various gutter profiles, including K-style, half-round, and custom designs.

By producing gutters directly at the construction site, gutter machines reduce the need for multiple sections, which can cause leaks and require more maintenance over time. This on-demand fabrication ensures that every gutter installation is precise and tailored to the project.

Advantages of Using Gutter Machines

1. Precision and Customization

One of the main advantages of gutter machines is their ability to produce seamless gutters with exact measurements. Traditional sectional gutters have joints that are potential weak points where leaks can develop. Seamless gutters created by machines eliminate these joints, reducing the risk of water damage. Contractors can also customize the length, shape, and style of the gutters, ensuring a perfect fit for any building.

2. Faster Installation

Gutter machines significantly speed up the installation process. Producing gutters on-site eliminates the need to measure, cut, and assemble multiple pieces manually. This efficiency not only reduces labor time but also allows contractors to complete projects more quickly, improving workflow and increasing profitability.

3. Cost-Effectiveness

While gutter machines require an initial investment, they provide long-term savings. By producing seamless gutters on-site, contractors reduce material waste, minimize labor hours, and prevent errors that could result in costly rework. Over time, these machines pay for themselves by delivering faster, more accurate installations with fewer issues.

4. Durability and Longevity

Seamless gutters produced by machines are more durable than traditional sectional systems. Fewer joints mean fewer points of failure, reducing the likelihood of leaks, corrosion, or damage over time. Many machines can also work with coated metals that resist rust and environmental wear, ensuring gutters remain functional and visually appealing for decades.

5. Professional Results

Gutter machines enable contractors to deliver consistent, professional-quality gutters. Smooth edges, precise dimensions, and uniform profiles create a polished appearance that enhances the overall look of a property. Clients benefit from both functional reliability and aesthetic appeal.

Types of Gutter Machines

Gutter machines come in different sizes and capabilities, tailored to various project requirements:

1. Portable Gutter Machines

Portable machines are compact and lightweight, suitable for residential projects or small-scale commercial work. They are easy to transport and can handle standard metal coils efficiently, making them ideal for on-site gutter fabrication.

2. Industrial Gutter Machines

Larger and more powerful, industrial gutter machines are designed for high-volume production. They are commonly used by commercial contractors or manufacturers who produce gutters for multiple projects. These machines can handle thicker metals and create longer continuous gutters with consistent precision.

3. CNC-Controlled Gutter Machines

Some advanced gutter machines feature computer numerical control (CNC) technology. CNC machines automate the fabrication process, ensuring maximum accuracy and reducing the potential for human error. They are particularly useful for large-scale projects or complex architectural designs that require custom profiles and precise measurements.

How Gutter Machines Work

Gutter machines operate on a simple yet efficient principle. A metal coil is fed into the machine, where rollers and shaping mechanisms form the gutter profile. The machine also includes a cutting system that trims the gutter to the desired length. Operators can adjust settings for different materials, thicknesses, and profiles, producing seamless, ready-to-install gutters on-site.

Key components include:

· Rollers: Shape the metal into the desired gutter profile.

· Cutting Mechanism: Cuts the gutter to precise lengths.

· Feeding System: Moves the metal coil smoothly through the rollers.

With proper use, gutter machines create custom, leak-resistant gutters that meet the exact specifications of the building.

Maintenance and Safety Tips

To ensure longevity and safe operation, gutter machines require regular maintenance and careful handling:

· Lubricate Moving Parts: Keep rollers and feed systems well-oiled.

· Inspect for Wear: Check rollers, blades, and alignment regularly.

· Clean After Use: Remove metal shavings and debris to prevent malfunctions.

· Operator Training: Only trained personnel should operate the machine.

· Protective Gear: Gloves, safety glasses, and sturdy footwear are essential.

Routine maintenance ensures the machine performs consistently and produces high-quality gutters for years.

Applications of Gutter Machines

Gutter machines are versatile and widely used in construction projects:

· Residential Roofing: Produce seamless gutters for homes, enhancing aesthetics and durability.

· Commercial Buildings: Fabricate large, continuous gutters for offices, warehouses, and industrial facilities.

· Roof Renovations: Replace damaged gutters with exact replacements, reducing water damage risk.

· Architectural Projects: CNC machines allow custom gutter profiles for unique designs.

By enabling precise, on-site gutter fabrication, these machines provide flexibility for various construction needs.

Conclusion

Gutter machines have transformed gutter fabrication and installation, offering precision, efficiency, and long-term durability. Seamless gutters produced by these machines reduce leaks, save time, and provide professional results that enhance both the functionality and appearance of a building.

Join our community to interact with posts!