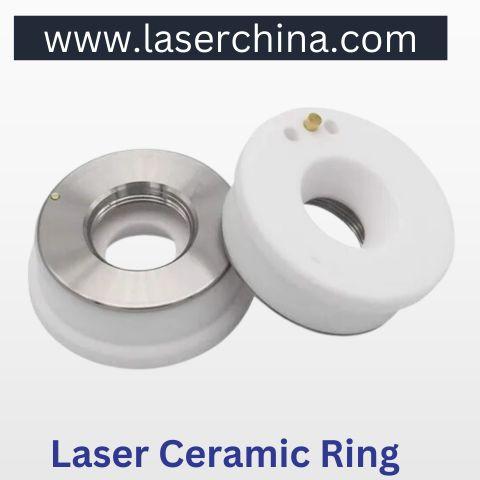

The Laser Ceramic Ring is a critical precision component widely used in modern laser cutting and welding systems. Designed to withstand extreme temperatures and intense laser energy, this small yet powerful part plays a major role in maintaining cutting accuracy and protecting sensitive laser heads. At LaserChina, Laser Ceramic Rings are engineered with high-grade technical ceramics to deliver long-lasting performance, consistent beam stability, and superior operational reliability for industrial laser applications.

What Is a Laser Ceramic Ring?

A Laser Ceramic Ring is a protective and insulating component installed inside laser cutting heads, especially fiber laser systems. Its primary function is to isolate the nozzle from the cutting head, ensuring electrical insulation, heat resistance, and precise laser beam alignment. LaserChina manufactures ceramic rings with strict dimensional accuracy to ensure seamless compatibility with a wide range of laser machines and cutting heads.

Advanced Material Quality by LaserChina

LaserChina uses premium industrial ceramic materials that offer excellent thermal stability and mechanical strength. The ceramic composition is carefully selected to handle high-power laser output without deformation or performance loss. This material quality ensures that the Laser Ceramic Ring remains stable even during long, continuous cutting operations, making it a trusted choice for demanding industrial environments.

High Precision Manufacturing Standards

Precision is essential in laser systems, and LaserChina understands this deeply. Every Laser Ceramic Ring is produced using advanced machining and quality control processes. Tight tolerances and smooth surface finishes help maintain perfect alignment between the laser beam and the nozzle. This precision directly contributes to cleaner cuts, reduced operational interruptions, and consistent production results.

Electrical Insulation and Safety Advantages

One of the key advantages of the Laser Ceramic Ring is its excellent electrical insulation capability. LaserChina ceramic rings effectively prevent electrical interference between the laser head and nozzle, enhancing machine safety and operational stability. This insulation helps protect expensive laser components while ensuring smooth and reliable cutting performance.

Heat Resistance for High-Power Laser Systems

High-power laser machines generate intense heat during operation. LaserChina’s Laser Ceramic Ring is specifically designed to resist extreme temperatures without cracking or losing structural integrity. This heat resistance supports continuous operation and reduces the need for frequent component replacement, improving overall machine efficiency and uptime.

Improved Cutting Accuracy and Stability

A well-designed Laser Ceramic Ring directly impacts cutting accuracy. LaserChina ceramic rings help maintain consistent nozzle positioning and stable laser output. This stability results in precise kerf widths, smooth edges, and uniform cutting quality across different materials such as stainless steel, carbon steel, and aluminum.

Compatibility with Various Laser Cutting Heads

LaserChina offers Laser Ceramic Ring solutions compatible with multiple laser cutting head models and configurations. Whether used in fiber laser cutting machines or automated industrial systems, these ceramic rings integrate smoothly, supporting flexible applications and diverse production requirements without compromising performance.

Cost-Effective Long-Term Performance

While small in size, the Laser Ceramic Ring contributes significantly to reducing maintenance frequency and protecting high-value laser components. LaserChina’s durable ceramic rings offer long service life, helping businesses lower operational costs over time while maintaining consistent production quality.

Applications Across Multiple Industries

The Laser Ceramic Ring from LaserChina is widely used in metal fabrication, automotive manufacturing, aerospace components, and precision engineering industries. Its reliability and performance make it suitable for both high-speed production lines and detailed custom cutting tasks, supporting a wide range of industrial needs.

Why Choose LaserChina for Laser Ceramic Rings

LaserChina is recognized for its commitment to quality, innovation, and customer-focused manufacturing. Each Laser Ceramic Ring reflects the brand’s dedication to precision engineering, strict quality standards, and dependable performance. By choosing LaserChina, users gain access to components designed to enhance laser efficiency and operational confidence.

Final Thoughts

The Laser Ceramic Ring is an essential component that significantly influences laser system performance, safety, and accuracy. LaserChina delivers high-quality ceramic rings that combine durability, precision, and advanced material science. For businesses seeking reliable laser components that support high-performance cutting and long-term productivity, LaserChina’s Laser Ceramic Ring stands as a smart and dependable solution.

Join our community to interact with posts!